Heat Pump-Based Drying

Reduces operating costs, decreases CO₂ emissions, improves the quality of the dried product and creates a safer system on the farm or industry.

Interested in heat pump-based drying?

Do you dry grain, seafood, food, wood or similar materials and are interested in heat pump-based drying? Contact Philip at +46 73-828 00 42 or email philip.jonsson@samster.se

Innovative heat pump-based hot air process for drying

We have developed a hot air process based on heat pump technology with integrated energy recovery and the utilization of solar energy. In grain handling, among other applications, this technology has the potential to provide many benefits, such as reduced operating costs, lower CO₂ emissions, improved quality of dried products, and a safer system on the farm.

Samster has received support from the European Innovation Partnership (EIP) to form an innovation group and carry out this project in collaboration with Agroväst, Akron, Steierpump AB, and Smörtvets Entreprenad & Lantbruk. The prototype developed in the project is intended to replace or complement a conventional oil burner in existing grain dryers, which is an important step toward the commercialization of this technology.

Read more about the project hereLower drying costs and reduced risks

The use of fossil fuels for drying contributes to the agricultural sector’s carbon dioxide emissions. Transitioning from fossil fuels to electrification and renewable energy helps reduce this climate impact. In the future, the demand for biofuels is expected to increase across several sectors. This could lead to higher prices, reduced availability due to increased competition, and an inability to sustainably meet Sweden’s high demand for biofuels. Regardless of the energy source, combustion poses a fire risk and contributes to local air pollution.

Our goal is to develop a solution that eliminates the various risks associated with purchased fuels.

In Sweden, the majority of grain is dried in hot air dryers powered with heat from oil, gas or biofuels. Large amounts of energy are used for hot air drying, and rising energy prices have increased interest in energy-saving solutions. The challenge that heat pump-based drying aims to solve is to lower drying costs for grain, among others. The solution utilizes solar energy combined with other energy-saving technologies. The result is a hot air process that is reliable, cost-effective, and fossil-free.

Multiple applications

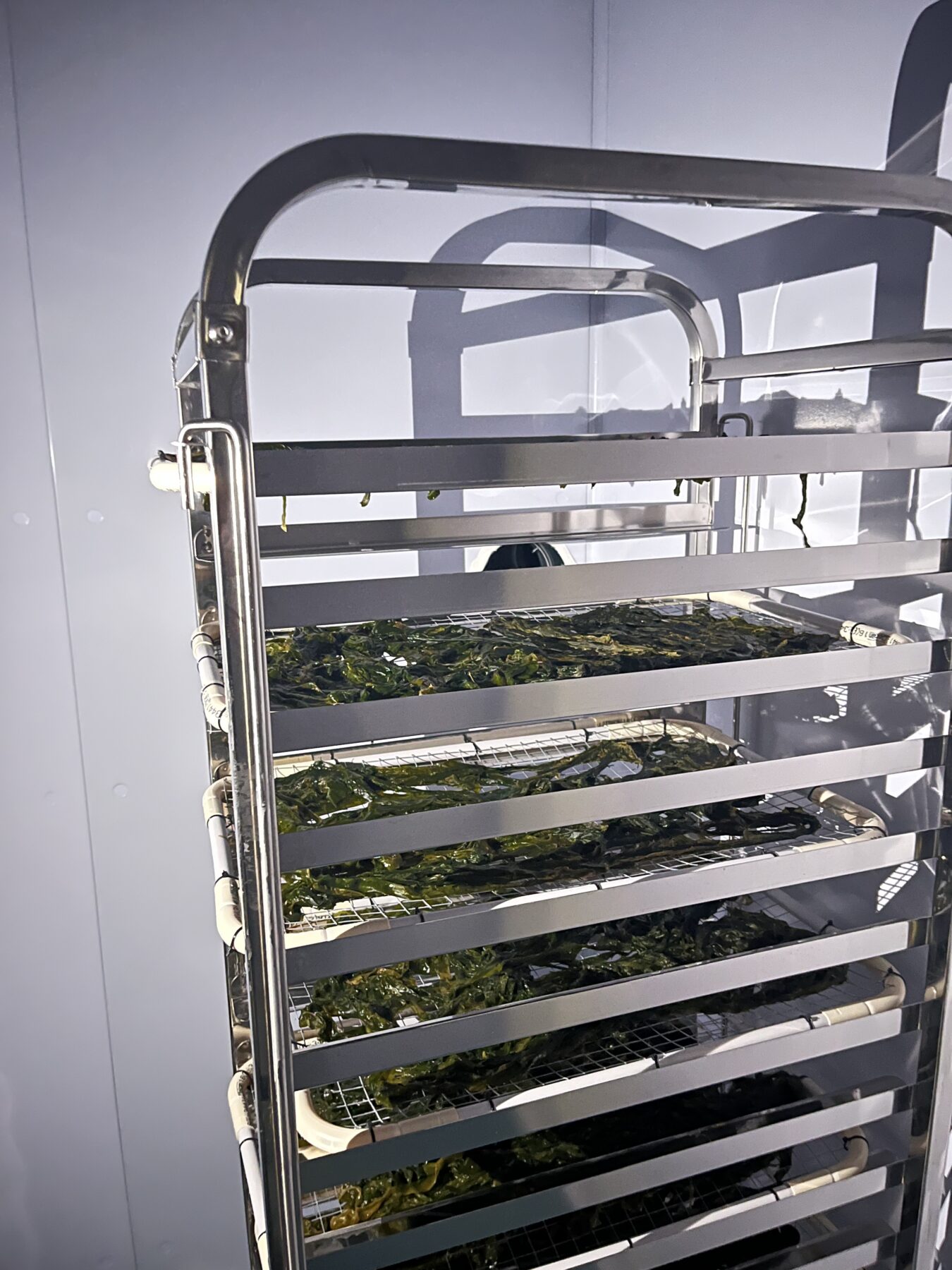

The gentle process makes heat pump-based drying ideal for a wide range of materials. It can be applied to grain, food products, raw materials, and other resources. So far, we have dried wheat, barley, rye, oats, seaweed, shrimp shells and mussels.

Do you dry grain, seafood, food, wood or similar materials and are interested in heat pump-based drying? Contact Philip at +46 73-828 00 42 or email philip.jonsson@samster.se